Case

Saving 100.000 USD a year in Kenya

Saving 100.000 USD a year in Kenya

Location: Kabatini, Kenya

Drinking water companies in the Netherlands do special projects worldwide to improve the quality of installations but also support the local engineering.

In Kabatini, Kenya, a well field with eight boreholes, nearly all with high maintenance cost, needed to be analyzed for replacement with high efficiency pumps.

This project was important for both the village and the investors to create a base document for the project approval of an estimated value of 1 million USD.

Assignment

Improve the selection of the pumps and teach the importance of data trending and pump control to the local engineers.

Surge tanks located at the manifold – © Oveducon

Execution

To ensure that the team would be able to optimize the current situation with all the well pumps, and since time was limited, we decided to work with one well field as an example.

Therefore we took an educational approach and worked step by step, whereas guidance was given for EPANET and Pipe Flow Expert software for network analysis and pump selection. In this way the local engineers would be able to duplicate the effort on all the other well fields.

“Assumptions were made without hydraulic modeling and proper friction loss calculations.”

First, we started with a full team meeting to get to know all the people involved with the data collection and those responsible for the calculations.

During this meeting, it was found that the overall impression of the local engineers and managers was that the pipelines were too small, and that some of the pumps were just not efficient enough. Their idea was to only replace the motors with high efficiency motors and frequency inverters to make these pumps run better. The problem here was that all assumptions were made without hydraulic modeling and proper friction loss calculations.

Manifold with broken valves and closed breather valves – © Oveducon

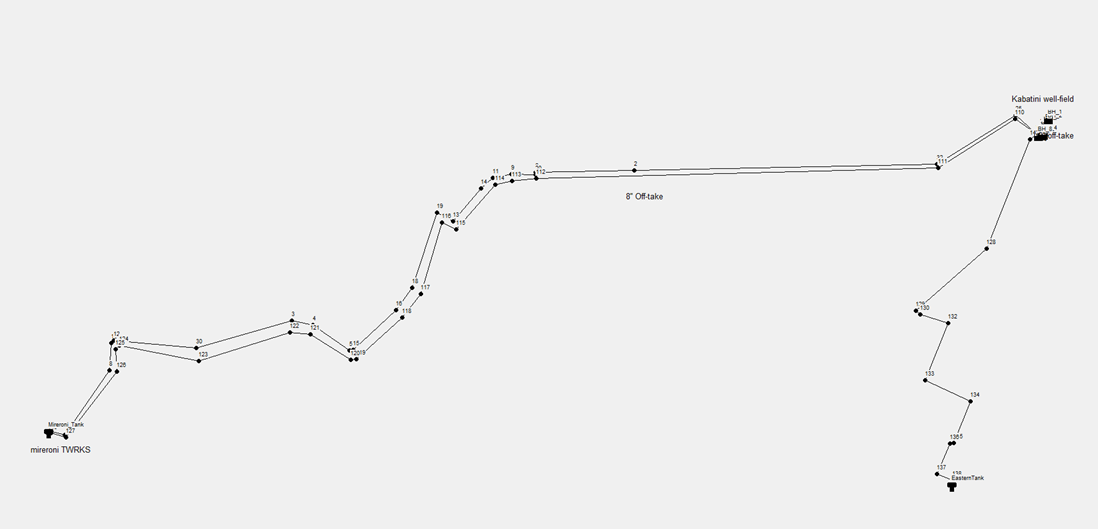

We started with getting all the data into EPANET (a software application used throughout the world to model water distribution systems) by putting the pumps inside the program and list all details in the proper data fields.

More like this

in your mailbox

Model in EPANET – © Oveducon

After completing the data input we were able to successfully model the flow and pressure of all the pumps of the Kabatini well field.

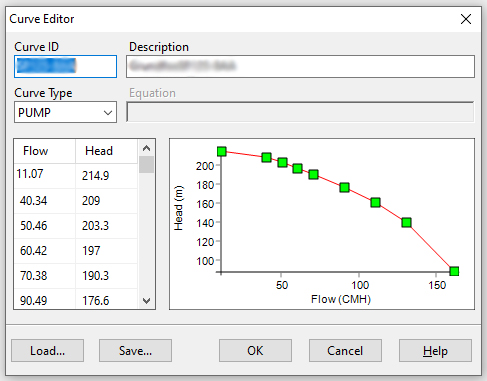

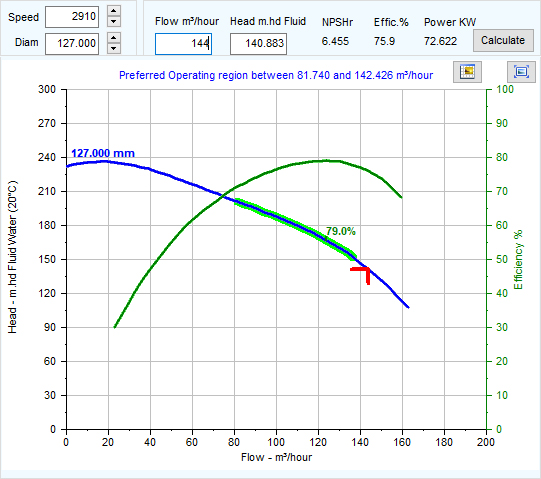

With EPANET we could not identify with enough clarity which pumps were outside the preferred operating range. Therefor we gave one of the local engineers a detailed training course in Pipe Flow Expert (an engineering program to model pump and piping systems). During this training we also created all the curves of their current pumps.

From the examples below, it becomes clear why we needed to use Pipe Flow Expert to get the required details to calculate the inefficiencies of the pumps that were currently installed.

Pump graph in EPANET – © Oveducon

Pump graph in Pipe Flow Expert – © Oveducon

During this project, we were able to make significant improvements to the report by:

- Calculating all the pumps

- Calculating the hydraulics on the existing supply line and verify the suitability of the pipeline sizing

- Implementing the request to install instrumentation and a control panel for better control of the pump discharge pressure and flow control

- Advising on the need for Frequency Inverters (VFD) for harmonizing the pumps that are operating parallel and feeding the same water supply line.

Results

As a result of the full analysis and identified insufficiencies, they were able to complete the other well field studies by themselves.

The final report got much more detail on the pumps and got approved by the financial sponsors.

Annual savings of more that 100K USD will be realized due to proper pump sizing, resulting in reduced maintenance and improved water supply.

With a proper control system, including frequency inverters on the pumps, the water supply will be more stable with less downtime.

Learn more

Our mission:

On a mission to help pump industry professionals raise the bar.

There is a huge waste of money, energy, time and resources in the pump industry due to a serious lack of technical know-how.

We are a group of passionate pump experts here to make a difference by sharing our decades of experience.

Our mission:

On a mission to help pump industry professionals raise the bar.

There is a huge waste of money, energy, time and resources in the pump industry due to a serious lack of technical know-how.

We are a group of passionate pump experts here to make a difference by sharing our decades of experience.

Follow

Help

Connect